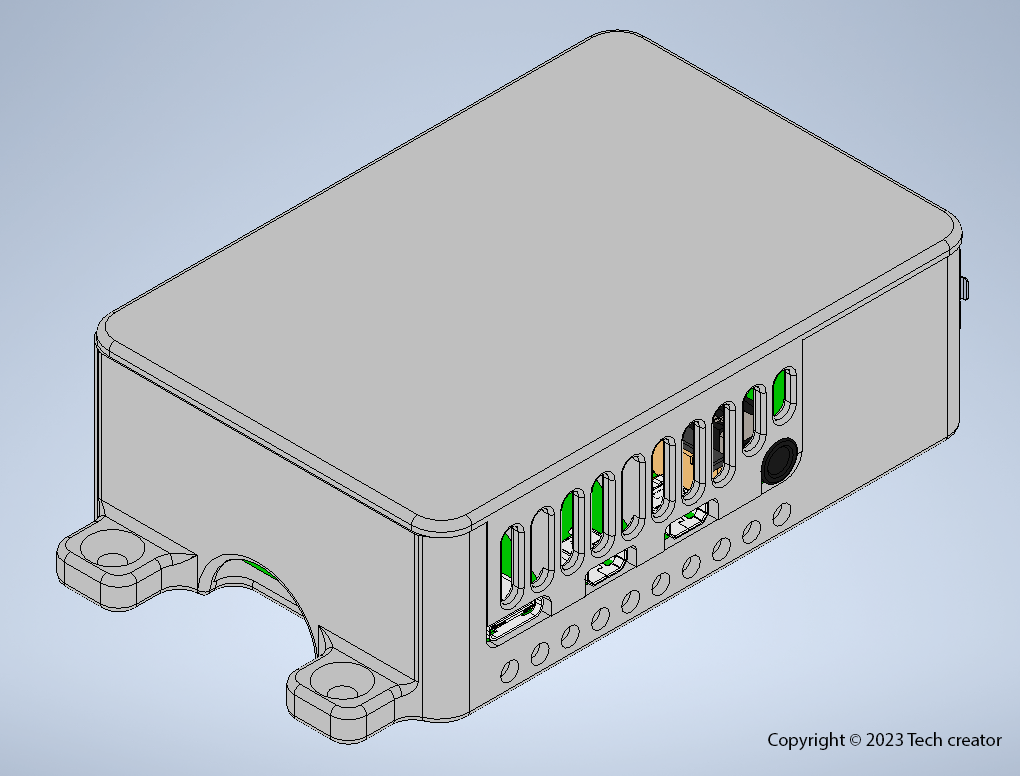

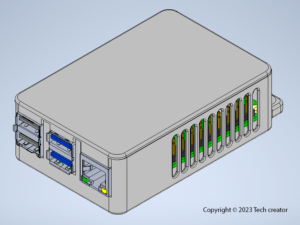

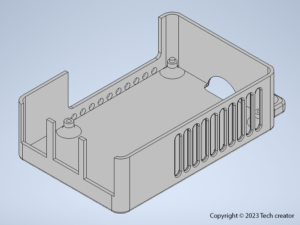

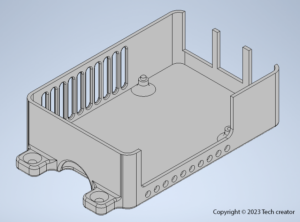

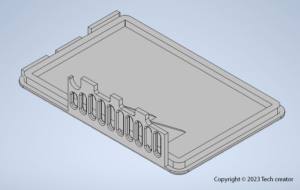

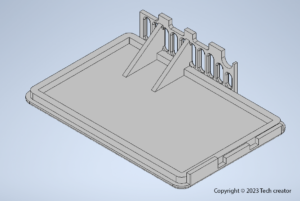

This design is for a compact, efficient housing specifically tailored for the Raspberry Pi 4. It features a unique structure that allows for 3D printing without the need for additional support materials. The housing incorporates passive cooling with strategically placed channels that ensure optimal airflow around the device, reducing the need for a fan. Notably, the design of the housing is ingeniously crafted to secure the Raspberry Pi 4 without the need for screws, ensuring a snug and stable fit. Additionally, the layout is streamlined to provide easy access to all ports and connectors, while ensuring the Raspberry Pi remains securely enclosed. The design includes two robust lashes on the exterior, enabling the housing to be firmly fixed to a mounting area with screws. The overall design is minimalist and functional, focusing on enhancing the Raspberry Pi’s performance and longevity.

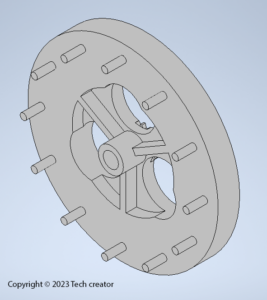

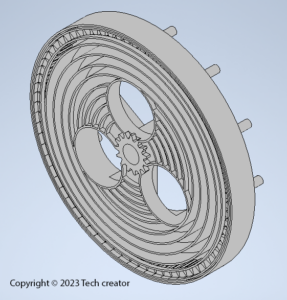

This design exemplifies a precise gear, reverse-engineered for the antenna assembly of a German car model. Developed in 2017, it was a response to the original part being broken, showcasing an innovative approach in 3D printing for automotive repair. The project involved meticulously reconstructing the gear’s design, ensuring it matched the mechanical requirements of the vehicle’s antenna system. At that time, slicing software did not automatically generate support structures, necessitating the integration of custom-designed supports within the design. These supports were critical in maintaining the structural integrity and detailed accuracy of the gear during the 3D printing process. The design was carefully tailored, considering material properties and optimal print orientations, to produce a durable and functional component. This endeavor not only solved an immediate mechanical problem but also stood as a pioneering example of using 3D printing and reverse engineering in the automotive industry.